Precision control is a key component in modern filling machines, where accuracy, consistency, and efficiency are crucial for meeting production standards.

Advanced control technologies help manufacturers achieve high-quality output across a wide range of products, whether in food, beverages, pharmaceuticals, or cosmetics. This article explores the latest control technologies in filling machines and how they enhance production reliability and precision.

1. Advanced Sensor Integration

Sensors play a critical role in ensuring precise fill levels. Modern filling machines incorporate various sensors, such as photoelectric, ultrasonic, and laser sensors, to detect bottle positions, measure fill levels, and monitor flow rates. Photoelectric sensors are particularly effective for detecting the presence or absence of containers on the production line, which prevents wasted product and helps streamline the filling process.

Ultrasonic sensors are often used for non-contact level measurements, which is especially beneficial when handling chemicals, as they avoid direct contact and prevent contamination. By gathering real-time data, these sensors enable the machine to adjust filling amounts instantly, maintaining the accuracy needed for high standards.

2. Servo Motor Systems

Servo motor systems provide exceptional control over the filling process, allowing manufacturers to adjust speed, torque, and position with high accuracy. Servo-driven piston fillers, for instance, are widely used for thick, viscous substances like creams and sauces. These systems enable precise control over the piston’s motion, allowing for exact fill volumes even at high speeds.

For industries where precision and hygiene are essential, servo motors ensure that each unit receives the same amount of product, which reduces both waste and variation. Additionally, servo-driven machines can be easily programmed and reprogrammed for different fill volumes, making them versatile for multi-product lines.

3. Flow Meter-Based Filling

Flow meter-based filling machines use either magnetic or mass flow meters to measure the exact amount of liquid that passes through the machine.

Magnetic flow meters, suitable for conductive liquids, use electromagnetic induction to measure flow rates accurately, while mass flow meters are best for denser, non-conductive products. These systems ensure that every container receives the same amount, irrespective of product viscosity.

Flow meter technology is especially advantageous in industries like pharmaceuticals and chemicals, where exact dosages are crucial for both regulatory compliance and consumer safety. This technology also allows for clean-in-place (CIP) systems, reducing downtime for cleaning and enhancing production efficiency.

4. PLC and HMI Integration

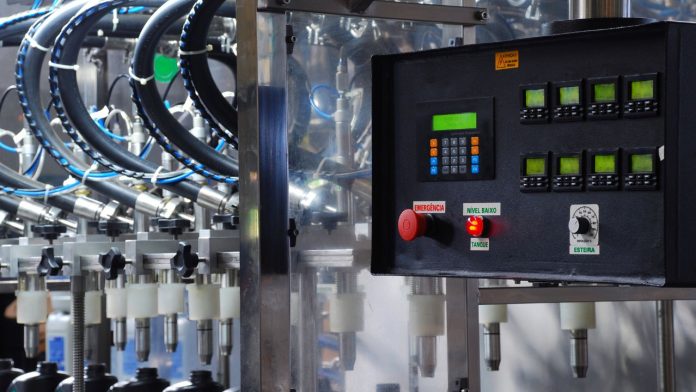

Programmable Logic Controllers (PLCs) and Human-Machine Interfaces (HMIs) are widely used in filling machines to control and monitor the entire production process.

PLCs receive data from sensors and motors, process it, and then send instructions to various machine components. This closed-loop system allows the machine to make instant adjustments based on real-time feedback.

Operators can use the HMI interface to monitor machine status, adjust settings, and perform diagnostics, making it easy to ensure consistent filling accuracy. This user-friendly interface improves productivity, reduces operator error, and allows for remote monitoring, enhancing both precision and convenience.

5. Applications Across Industries

Precision filling technology is beneficial across numerous industries. In the beverage industry, high-precision fillers ensure consistent fill levels, minimizing spillage and adhering to packaging standards. For the pharmaceutical sector, precision filling guarantees that medications meet regulatory dosage requirements. Cosmetics manufacturers benefit from accurate filling to maintain product consistency, while chemical producers rely on precision filling to ensure safe and accurate packaging.

Conclusion

Precision control technology has transformed filling machines, making them indispensable tools for industries that demand accuracy and efficiency. The integration of advanced sensors, servo motors, flow meters, and PLCs ensures that filling processes remain precise, reliable, and efficient. For those seeking tailored solutions with cutting-edge precision technology, learn more about Confilling.