Choosing die casting for your casting needs may be a wise choice, depending on what you need. Die casting uses metals to form two dies that will act as an injection mold. This article will explain a die cast and every detail you need to know.

What is die casting?

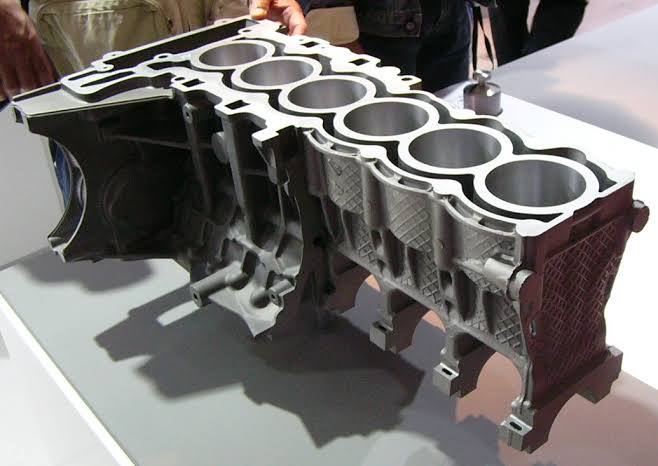

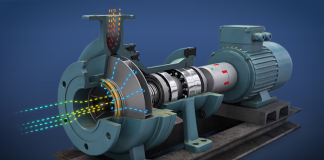

Die casting is a popular method in the casting industry for metals. The process is simple: all you want to do is to turn metal that you have melted into a cavity. This process occurs under very high pressure, so you need to be careful. When you have your mold cavity, it will form into a double steel die that has been hardened. These two dies will now act as the injection mold of the process. The dies already have the shape of the injection mold, so it is not a complex procedure to act as it. Most of the time, die casting uses metals that have no iron additions. Good examples of metals include aluminum, copper, lead, magnesium, amongst others. There are two options of the chamber you can use for your die casting. It’s either the hot or cold chamber. The one you choose will depend on the metal you cast.

What is the history of die casting?

Die casting is one of the oldest serving types of Casting methods, with a history going into the 17th century. The process came into being in 1838, and its primary purpose was to make movable parts necessary in the industry of printing. In 1849, the first ever production from die casting was produced, and the patent got a grant. The idea was to ensure that the printing procedure became movable. Another invention for die casting came in 1885, with Otto Mergenthaler building a machine through the die casting process.

What Are its geometric features?

If you want to work with a die cast, you need to understand the geometric features involved with the die casting. Some of these geometric features include;

- Parting Line. It is a point of intersection between two ends of a mold during the die casting process. There are two parts involved with the Parting line: the ejector and cover. The side that will be the ejector and cover depends on the parting line.

- Filet. The filet is a part of the die casting that could have occurred as an edge but suddenly is a curve.

- These are necessary parts of the die casting because they provide support.

What equipment will you need for die casting

Some advantages of die casting

Conclusion

The choice of casting method you will choose for creating a component will depend on the type of component you are trying to make; however, that is not the only factor. The type of component, expert advice, and many others are the factors to consider. The equipment at hand is also vital. Die casting is one of the standard casting methods for making metal parts of a machine, but it may not exactly be the best option for you. With this article, we have explained what die casting is, the process of die casting, and how it is beneficial to you. If you are an expert, you can make a choice. But if you are not, you should call a casting expert before choosing the die cast or any other casting method.