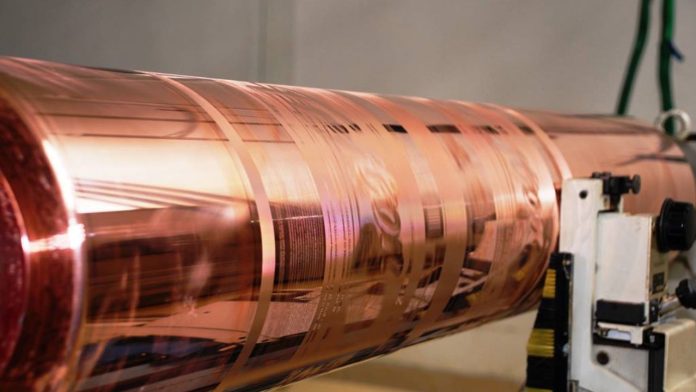

Gravure printing is an essential area whereby the quality and durability of the printing cylinders are critical. Copper plating is now used for high-precision plate rollers and is considered critical for the best performance and durability. In this article, the author examines the above components and explains why copper plating is essential to these parts, as well as its advantages and effects on gravure printing. Explore the link, https://www.laserengravingmanufacturers.com/how-to-make-high-precision-plate-cylinder-in-gravure-printing/.

Improving Print Quality

The copper plating is applied to improve print quality. The characteristics of the copper surface that determine the quality of printed images are its smoothness and levelness. This means that to ensure that the engraving is well done and improve the prints’ sharpness, the copper layer that is plated on the roller needs to be done well. The copper has a very smooth surface which is very useful in the transfer of intricate designs and fine details to the substrate surface hence its importance in high-quality prints.

Enhancing Cylinder Durability

The need to use copper plating in high-precision plate rollers cannot be overemphasized because of the contribution it makes to cylinder longevity. In gravure printing, the cylinders used for printing are under pressure and experience a lot of stress. Copper plating gives a hard layer that shields the base material from wear and tear as well as rusting. This layer greatly enhances the durability of the cylinders and decreases the rate of replacements and maintenance, which in turn lowers the overall expenses of the printing businesses.

Facilitating Better Ink Transfer

There is another important factor associated with gravure printing and it is the ability to transfer the ink properly. Copper plating helps in improving the ink reception and transfer characteristics of the cylinder. The copper surface is also characterized by good ink affinity so that the ink is uniformly spread on the cylinder. This leads to the harmonization of the color and tone of the printed items generated from the printer. It enhances the capability of ink to transfer on the paper which minimizes problems like ink streaking or blotching, thus enhancing the quality of prints and color accuracy.

Supporting High Precision

High-precision plate rollers have to be of high standards to meet the requirements of the new gravure printing. Copper plating is the most appropriate method since it offers the needed accuracy and precision of the engraving surface. The copper layer also makes it possible to generate fine features that are required for the generation of high-resolution prints. This precision is important for those uses that require sharpness like in the packaging and high-quality magazines.

Enhancing Heat Resistance

This type of printing is characterized by the production of a lot of heat during the actual printing process. Copper plating helps in the heat resistance of the rollers so that the rollers can work effectively in high temperatures. The thermal conductivity in copper enables the heat produced to be dissipated thereby preventing deformation or damage of the rollers. This heat resistance is important in avoiding the deformation of printing cylinders and hence ease of operation.

Conclusion

Copper plating is the most essential process in the field of gravure printing. It is used in the enhancement of the durability of prints, improvement of print quality, effective ink transfer, support of high precision, and heat resistance making it a core component in the printing industry. Through copper plating, the printing operations can attain the best results and meet the standards expected in today’s printing industry.